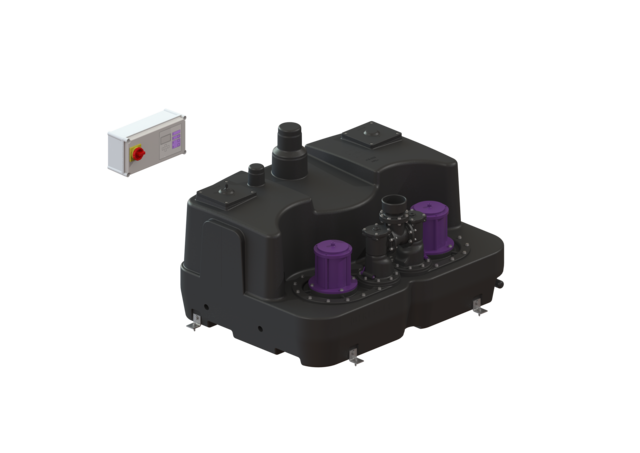

The Importance of Grease Separator Tanks in Commercial Kitchens

In the bustling world of commercial kitchens, where efficiency and hygiene are paramount, the role of grease separator tanks cannot be overstated. These unassuming devices play a crucial role in maintaining a smooth and safe operation, ensuring that both the kitchen staff and the environment are protected from the adverse effects of grease accumulation. In this article, we will delve into the significance of grease separator tank, exploring their functions, benefits, and the impact they have on the overall performance of commercial kitchens.

Grease Separator Tanks – A Shield Against Environmental and Health Hazards

In the fast-paced environment of commercial kitchens, the constant production of greasy wastewater poses a significant challenge. Without effective management, this grease-laden water can wreak havoc on both the environment and the health of individuals. Grease separator tanks act as a shield against these hazards, preventing the discharge of harmful substances into the sewage system.

Understanding the Role of Grease Separator Tanks

- Mechanism of Operation

At the heart of a grease separator tank lies a simple yet ingenious mechanism. As wastewater from the kitchen flows into the tank, the grease and oil, being lighter than water, naturally rise to the surface. The separator tank captures this floating grease, allowing the relatively cleaner water to pass through. This process ensures that the discharged water is free from the harmful effects of accumulated grease.

- Compliance with Regulations

In many jurisdictions, there are strict regulations governing the discharge of wastewater from commercial kitchens. Grease separator tanks play a pivotal role in helping establishments comply with these regulations. By preventing the release of excessive grease into the public sewer system, these tanks contribute to the overall environmental health of the community.

The Benefits of Installing Grease Separator Tanks

- Environmental Impact

One of the primary benefits of grease separator tanks is their positive impact on the environment. When grease-laden water enters the sewage system unchecked, it can lead to blockages and overflows. These incidents not only pose a threat to aquatic ecosystems but can also result in costly clean-up operations. Grease separator tanks mitigate these risks by capturing grease before it can cause harm.

- Avoiding Pipe Blockages

Grease buildup in pipes is a common issue in commercial kitchens. Over time, the accumulation of grease can lead to blockages, causing slow drainage and, in severe cases, complete pipe failure. Grease separator tanks act as a preventive measure, reducing the amount of grease that reaches the pipes and ensuring a clear and unobstructed flow of wastewater.

- Extending the Life of Sewage Infrastructure

The installation of grease separator tanks not only benefits individual establishments but also contributes to the longevity of the public sewage infrastructure. By reducing the influx of grease into the municipal sewer system, these tanks help prevent the deterioration of pipes and sewage treatment facilities. This, in turn, translates to lower maintenance costs for local authorities.

The Economic Value of Grease Separator Tanks in Commercial Kitchens

Grease separator tanks not only fulfill a critical environmental role but also offer tangible economic benefits to commercial kitchens. The initial investment in these tanks is often outweighed by the long-term savings and advantages they provide.

Cost Savings Through Preventive Maintenance

- Reduced Plumbing Costs

The prevention of pipe blockages through the use of grease separator tanks translates to reduced plumbing costs for commercial kitchens. Regular maintenance and cleaning of pipes can be a significant expense, and by minimizing the accumulation of grease, these tanks help kitchens avoid these unnecessary costs.

- Lowered Wastewater Treatment Expenses

Wastewater treatment facilities are designed to handle a certain volume and composition of wastewater. Excessive grease can strain these facilities, leading to higher treatment costs. Grease separator tanks ensure that only properly treated water enters the municipal system, avoiding additional treatment expenses.

Enhanced Kitchen Efficiency and Safety

- Uninterrupted Workflow

The efficient operation of a commercial kitchen relies on a seamless workflow. Grease separator tanks contribute to this by preventing unexpected drainage issues and allowing kitchen staff to focus on their tasks without the disruption caused by plumbing problems.

- Fire Prevention

Accumulated grease in exhaust systems and ducts poses a significant fire hazard in commercial kitchens. Grease separator tanks, by reducing the overall grease load in wastewater, contribute to fire prevention measures, enhancing the safety of the kitchen environment.

Choosing the Right Grease Separator Tank

Selecting an appropriate grease separator tank is crucial for ensuring its effectiveness in a commercial kitchen. Various factors, including the size of the kitchen, the volume of wastewater generated, and local regulations, must be considered.

Size Matters – Matching the Tank to Kitchen Needs

- Calculating Wastewater Flow

To determine the appropriate size of a grease separator tank, it’s essential to calculate the average flow of wastewater from the kitchen. This includes water from sinks, dishwashers, and other sources. By selecting a tank that can handle the expected volume, the efficiency of grease separation is optimized.

- Considering Peak Usage

Commercial kitchens often experience peak hours of operation where wastewater production is at its highest. The grease separator tank should be sized to accommodate these peak periods, ensuring that it doesn’t become overwhelmed during times of increased activity.

Maintenance Requirements for Long-Term Performance

- Regular Cleaning Schedule

Maintenance is key to the long-term performance of grease separator tanks. Establishing a regular cleaning schedule is essential to prevent the buildup of grease and ensure the tank continues to operate efficiently. Neglecting maintenance can lead to decreased separation efficiency and potential issues with the sewage system.

- Inspection and Repairs

Periodic inspections of the grease separator tank are necessary to identify any wear and tear, corrosion, or malfunctions. Prompt repairs and replacements of damaged components are crucial to avoid system failures and maintain the tank’s effectiveness.

Conclusion

Within the intricate network of activities within commercial kitchens, Kessel Grease Separator tanks emerge as silent champions, playing a crucial role in upholding cleanliness, efficiency, and adherence to environmental regulations. Undeniably, their influence on the durability of sewage infrastructure, financial savings for businesses, and the overall safety within kitchen spaces is immeasurable. As commercial kitchens progress, adopting technologies and methodologies that prioritize sustainability and efficiency, the significance of Kessel Grease Separator tanks becomes increasingly pivotal. It extends beyond mere compliance; it evolves into a strategic investment fostering the seamless operation and enduring success of commercial kitchens. In regions like the UAE and Dubai, where adherence to such practices is crucial, partnering with reputable Water Pump Suppliers in UAE and Water Pump Suppliers in Dubai becomes integral for the optimal performance of systems intertwined with Kessel Grease Separator technology.