6 Tiny But Important Things to Observe in Black Magnetic Boxes Wholesale Production

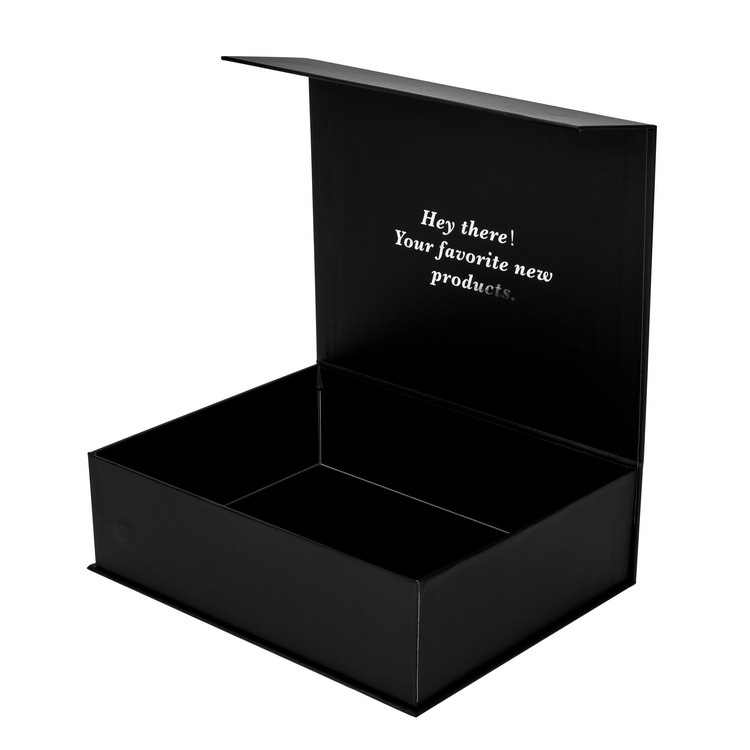

The production of black magnetic boxes at a wholesale level requires meticulous attention to detail to ensure the consistent quality and appeal of the final product. These elegant and versatile boxes have gained popularity across various industries for their luxurious appearance and practicality. In this article, we will explore six tiny but crucial details that you must observe in the wholesale production of black magnetic boxes to achieve the best results.

Materials Selection

In black magnetic boxes wholesale production, the choice of materials is of paramount importance. Opt for high-quality black paperboard or cardstock with a smooth, matte surface. The material should be thick enough to provide structural integrity and convey a sense of luxury. Selecting the right material ensures that the boxes are not only visually appealing but also durable and protective.

- Opt for high-quality black paperboard or cardstock with a smooth, matte surface.

- Ensure the material is thick enough for structural integrity and a sense of luxury.

Color Consistency

Achieving uniform black Magnetic Boxes Wholesale is essential for the overall aesthetics of the boxes. Ensure that the black ink or colorant used is consistent throughout the production process. Any variations in color can be distracting and may diminish the perceived quality of the boxes. Regularly monitor the color consistency to maintain a professional appearance.

- Achieve a uniform black color throughout the production process.

- Monitor color consistency regularly to maintain a professional appearance.

Magnetic Closure Strength

The magnetic closure is a defining feature of these boxes, and its strength is critical. High-quality magnets with the appropriate strength should be used to ensure that the boxes remain securely closed during transport and handling. A weak magnetic closure can result in a subpar unboxing experience and potential damage to the contents, which can be detrimental to customer satisfaction.

- Use high-quality magnets with the appropriate strength for a secure closure.

- A strong magnetic closure ensures a superior unboxing experience and content protection.

Print Quality and Clarity

The clarity and quality of the printed elements on the black magnetic boxes are essential. Attention to detail during the printing process is vital to ensure that text, graphics, and images appear crisp and sharp. The black ink should be rich without any uneven patches or streaks. Utilize the right printing techniques and technologies to achieve a flawless finish.

- Ensure printed elements like text, graphics, and images are crisp and sharp.

- Utilize the right printing techniques and technologies for a flawless finish.

Embossing and Debossing Precision

When incorporating embossing or debossing for added tactile appeal, precision is crucial. These techniques create raised or recessed patterns and textures on the Custom box surface. The precision and depth of embossing or debossing can greatly influence the perceived quality of the boxes. Ensure that these details are executed with care and accuracy.

- Precision is crucial when incorporating embossing or debossing.

- Ensure raised or recessed patterns and textures are executed with care and accuracy.

Quality Control Checks

Rigorous quality control checks are essential in black magnetic box wholesale production. Implement checks at various stages of production to identify and rectify any flaws or imperfections. These checks should encompass every aspect, from material quality to printing, embossing, debossing, and the functionality of the magnetic closure. Consistent quality control helps ensure that the final products meet the highest standards.

- Implement rigorous quality control checks at various production stages.

- Checks should cover material quality, printing, embossing, debossing, and magnetic closure functionality to meet the highest standards.

Conclusion

The success of black magnetic boxes wholesale production hinges on the observation of small but crucial details. Selection of high-quality materials, maintaining color consistency, ensuring a strong magnetic closure, achieving top-notch print quality, precise embossing and debossing, and implementing rigorous quality control checks are all vital aspects. By paying meticulous attention to these tiny yet important elements, you can consistently produce black magnetic boxes that not only protect the contents but also convey a sense of luxury and professionalism. This attention to detail will set you apart in the competitive world of wholesale packaging and leave a lasting impression on your customers.